SKU:

Callaham Guitars

Callaham Premium Upgrade Kit, American Standard Strat (Thru 2007)

Callaham Premium Upgrade Kit, American Standard Strat (Thru 2007)

Couldn't load pickup availability

- Country of Manufacture: USA

- Callaham Pop-in Arm Included, Please Select

- String Spacing: 2-1/16" (2.062" / 52.4mm)

- Enhanced Vintage block, w/ 10-32 Thread

- Fits Fender American Standard Stratocaster - through 2007; Strat Plus Deluxe

This kit includes all of the parts shown in the image above. It gives you everything you need to completely upgrade the Fender tremolo, retaining only the stock top plate and studs. Please note that these are the offset-screw saddles as used in older guitars; in 2008 Fender changed the saddles to a center-screw design. If you need center-screw saddles, then you'll need the 2008+ kit instead.

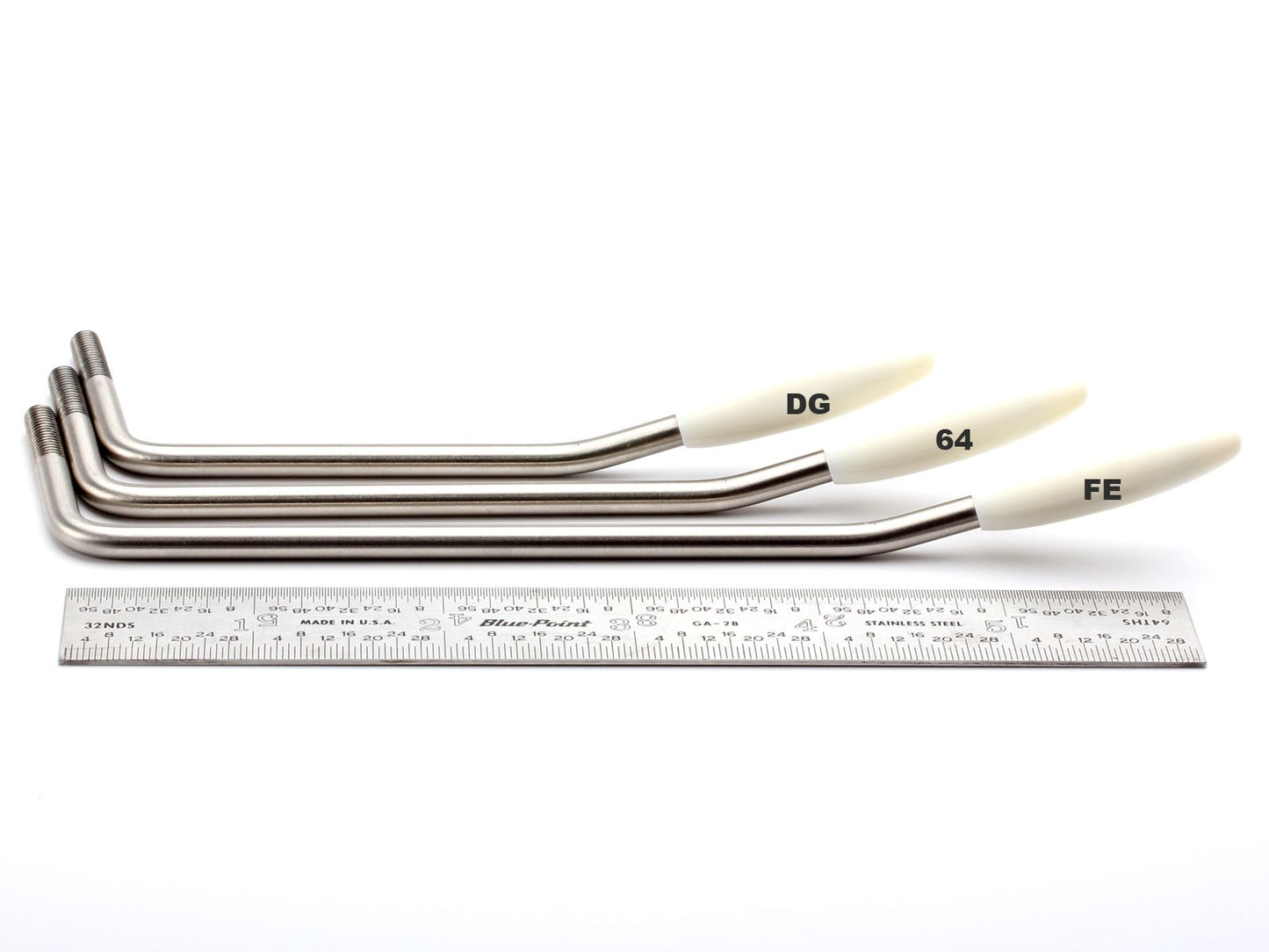

Available with three different arm lengths:

64 (5-1/4" length - based on '64 Strat)

DG (4-1/8" length - based on David Gilmour's black Strat)

FE (6" - based on current Fender production)

Please see the image of the three arms to help you choose which one you want. We stock Callaham's arms with parchment tips only -- because we stock the full spectrum of plastic parts from Fender, we do not stock other colors from Callaham.

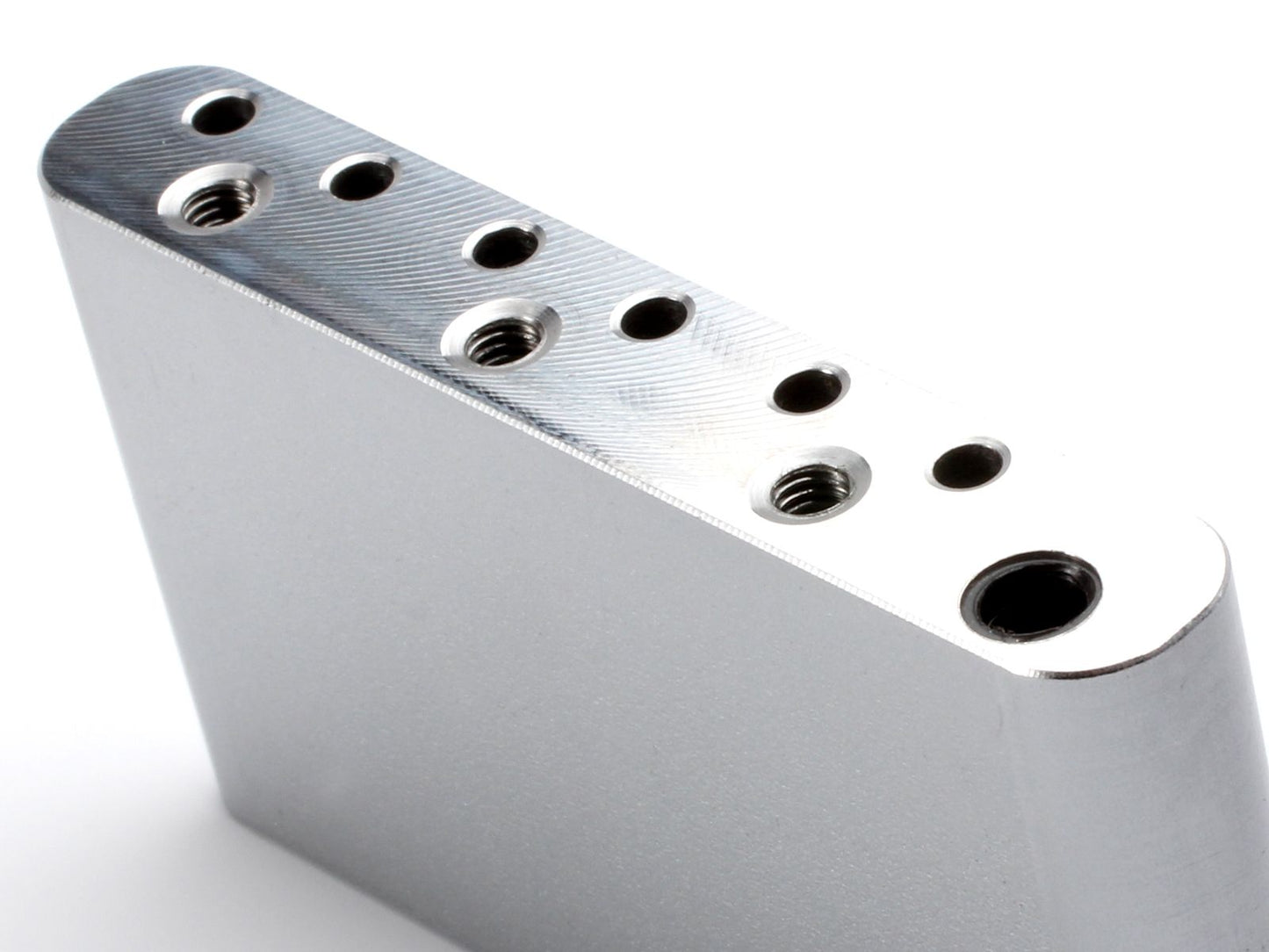

BLOCK

The blocks in all Callaham trems are made of 1018 cold-rolled steel like the vintage originals, which contributes to the sustain and harmonic content that has made these guitars legendary. Replacing a block made of inferior materials (zinc, leaded steel, sintered steel) with one of Callaham's blocks will get you one step closer to those $30,000 originals. All have a precision-machined top surface that is free of paint to ensure solid metal-to-metal contact with the top plate, for optimal tone.

Callaham's blocks are machined with shallow string ball holes, like the originals.

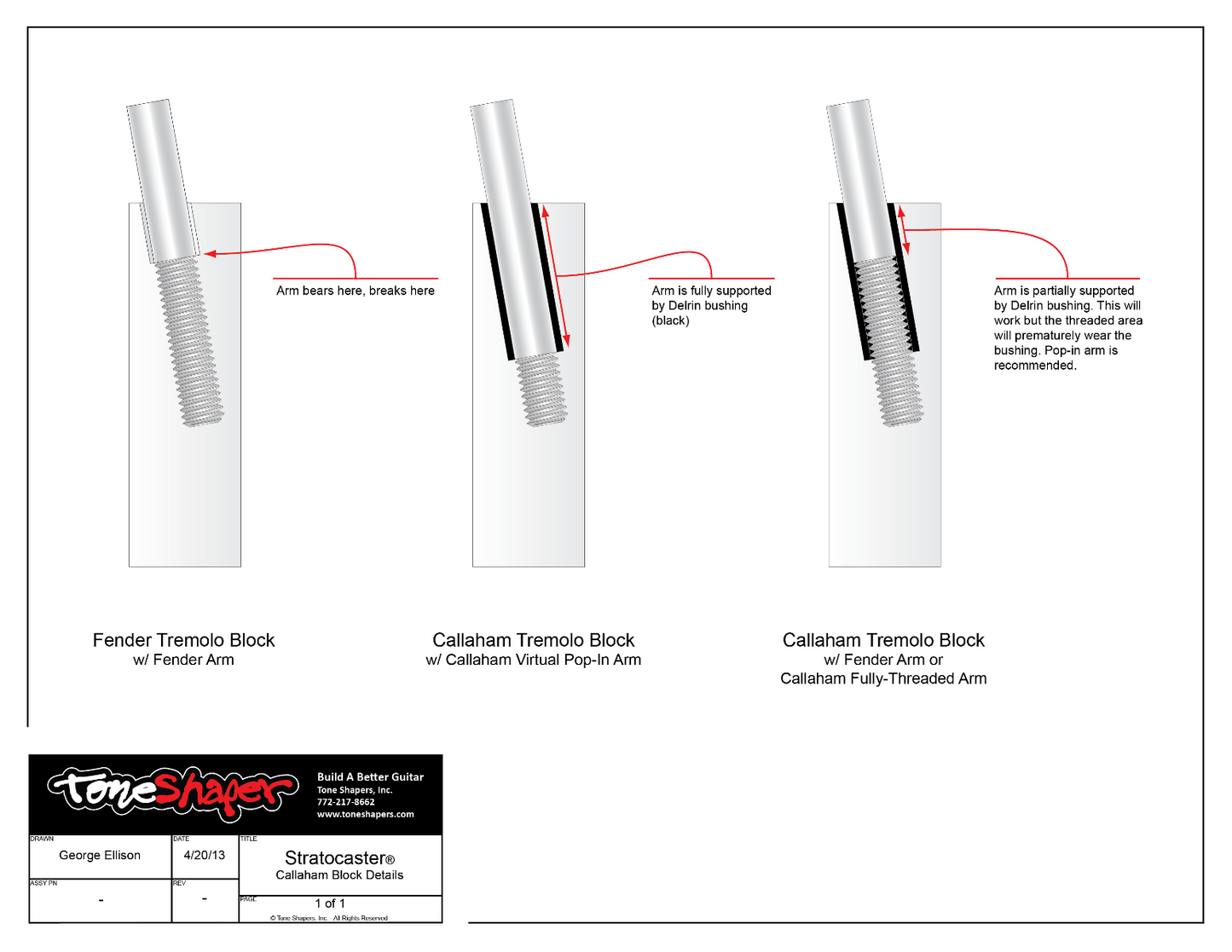

And all Callaham blocks come with a precision-reamed Delrin insert in the arm hole (Callaham's Enhanced Vintage design), which allows the tremolo arm to fit snugly and be free of play, without requiring a spring in the hole, as Fender's threaded blocks do. This gives you the best tremolo feel available, and without worrying about losing springs (in case you're unaware of it, new Stratocasters ship with a round label over the hole in the tremolo - the label's purpose is to prevent the tiny spring from falling out and being lost).

This feature also reduces the risk of broken trem arms. With traditional threaded block designs, when you use the arm you create forces that are concentrated right at the threaded portion of the arm - its weakest point. This is where arms typically break. Callaham's solution of leaving this bearing area of the arm unthreaded - coupled with the Delrin bushing that the arm bears against - virtually eliminates broken arms.

We include the "64" length arm by default; if you would prefer a different length, then please let us know at time of purchase via email, or add a comment to your payment via PayPal. We stock Callaham's arms with parchment tips only. We have Fender arm tips available in various colors at additional cost.

SADDLES

Callaham's saddles are designed from original pre-CBS saddles, with some improvements. Callaham has slightly lengthened the string slot as compared to pre-CBS saddles, so that the strings will not bind and bend against a sharp edge before going over the saddles, which reduces string breakage. Fender's current production saddles have their slots moved too far to the rear, causing string breakage and loss of downward pressure on the saddle, hurting both sustain and tone.

Callaham's saddles, like pre-CBS saddles, have threads running the entire height of the front skirt of the saddle. Fender's current production saddles have fewer threads and a shorter front skirt. Consequently, the Callaham height-adjustment screws are held more securely, with more thread contact, maintaining sustain and saddle stability.

There is a commonly-held belief that pre-CBS saddles were hardened, but Callaham states that every pre-CBS saddle they've tested measures on average only 50 Rockwell B. Callaham has chosen steel with a hardness of 95-98 Rockwell B for their saddles. Further, the steel work-hardens in the making of the saddle and is well over 115 Rockwell B where the string crosses.

Note that the Callaham saddles come with different spring lengths and height-adjustment screws, it's important that you install them in the right places:

- E: short spring, short screws

- A: short spring, long screws

- D: long spring, long screws

- G: long spring, long screws

- B: long spring, long screws

- E: long spring, short screws

maestro

these are the players who inspire us